Showing Our Working

As the Indie Manufacturing project progresses we want to share our thoughts, experiences and learning. We thought a good way to kick this off would be a mini interview with the person behind MCQN, Adrian McEwen.

Q. Can you give me a little background on who you are and what you do?

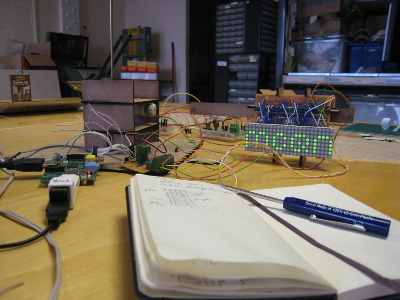

I’m Adrian McEwen. I run MCQN Ltd and, mostly, we connect strange things to the Internet. That could be machines to blow bubbles when someone tweets you, or sensors to monitor the performance of prototype wave energy generators, or anything in between. It’s normally termed “the Internet of Things”. Some of our work is for clients, but we’re most interested in developing our own products.

These are generally nearer to the consumer end of the bubble-machine-to-industrial-sensor spectrum, looking at how technology can escape from behind flat panes of glass and enrich our lives.

Q. Tell me about DoES Liverpool.

DoES Liverpool is many things, to many people. It’s home for MCQN Ltd and a collection of other businesses, freelancers, artists, remote workers based in Liverpool. It’s a blend of makerspace, office, events space and community. I joke that, given enough time, anyone doing anything interesting in Liverpool will cross the threshold for some reason or other.

Both the makerspace and the expertise available - and freely shared within the community are invaluable when developing products.

Q. And a little on the UK Maker Belt?

The UK Maker Belt is rather like the community side of DoES Liverpool but spun out across the North of England. Running loosely from Liverpool and Morecambe on the West coast over to Newcastle and Hull on the East, it focuses more on people in the businesses involved (in some capacity) in making - designers, wholesalers, suppliers and factories.

The UK Maker Belt Association is a trade association for the maker belt. It doesn’t take itself too seriously, but is looking to help connect and strengthen the existing ties between makers.

Q. Maker culture and the diversity of the people that make up the community have been pretty well documented. The term ‘indie manufacturer’ is new. What is an indie manufacturer and where do they fit in the maker ecosystem?

I don’t think the Maker Movement cares what scale your making is at it’s focused more on your passion and interest in making, regardless of what you’re making or how.

The “indie manufacturer” term is more for the benefit of a wider public. In the general perception making things seems polarized into two extremes - there’s either the high labour levels of “handmade” which approaches fetishizing the craft involved in making; or the dehumanised all-done-by-machine of corporate mass manufacturing.

Of course in reality things are much less demarcated. Products presented as handmade can involve some pretty advanced tools and human rights campaigners regularly expose the human labour that mass manufacturers would rather keep hidden.

“Indie Manufacturing” aims to make the middle ground more visible; to remind people that large manufacturers tend to start out as smaller ones; and encourage a more open discussion about the challenges of scaling up from individual maker.

Q. Navigating the middle ground between very short run ‘handmade’ items and the mass manufacturing is a challenge. What do you expect to be the major hurdles?

Good question. Probably the things I don’t know about. Of the ones that I do know about, certification is something that’s less well explored and/or talked about, plus one of the larger unavoidable costs.

With most of the rest of the exercise there’s at least an upper bound on the costs involved - in the worst case you can do things in the same way you would to make one, and it’ll just take longer to do lots; and in general as you scale up it unlocks ways to make things cheaper.

Working out when/how to decide between making things in-house and outsourcing them will be tricky, and I’ll probably get it wrong on some decisions. The aim would be to get as much as possible done externally, as that will scale better when(/if) the sales volumes grow, but there’ll be the temptation to do some of the things myself as it will look easier than continuing to scour the area for a company to take it on.

I expect there’ll be a combination of results like that, where I’ll learn that some things would have been better done internally and others I really should have outsourced - but it’s an iterative process and next time round I’ll have (I’d hope) a renewed appetite for working more of it out.

Speaking of sales, that’s another murky area. For the first batch it’s most likely that I’ll be dealing directly with customers. However, I have some ideas about people to talk to who would sell the items on, and I’ll be aiming to set the prices to allow that as a possibility. It’s hard to push forwards on that without a clear idea of who the target market is, so that’s something to work out while building the prototypes.